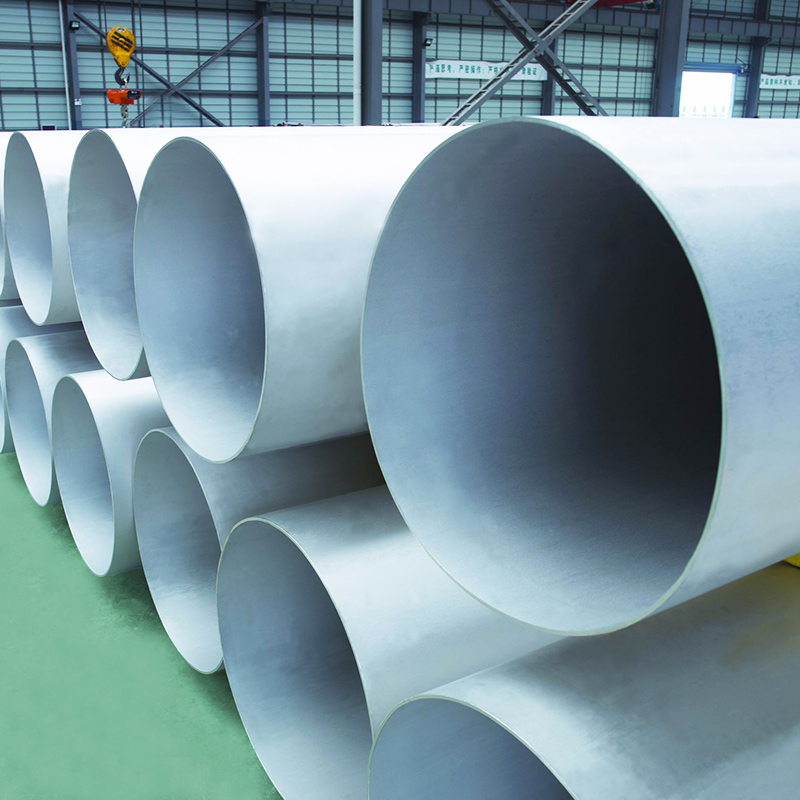

Panjelasan Produk

Pipa anu dilas tina stainless steel mangrupikeun komponén integral dina rupa-rupa industri kusabab daya tahan, tahan korosi, sareng serbaguna. Pipa-pipa ieu didamel ngalangkungan prosés pangelasan, ngahijikeun lambaran atanapi strip stainless steel pikeun ngabentuk tabung silinder. Ieu tinjauan lengkep ngeunaan pipa anu dilas tina stainless steel:

Bahan sareng Kelas:

● Séri 304 sareng 316: Kelas baja tahan karat tujuan umum anu umum.

● 310/S sareng 310H: Baja tahan karat tahan suhu luhur pikeun aplikasi tungku sareng penukar panas.

● 321 sareng 321H: Kelas tahan panas anu cocog pikeun lingkungan suhu anu luhur.

● 904L: Aloi anu tahan pisan kana korosi pikeun lingkungan anu agrésif.

● S31803: Baja tahan karat dupleks, anu nawiskeun kakuatan sareng tahan korosi.

Prosés Manufaktur:

● Las Fusi Listrik (EFW): Dina prosés ieu, sambungan longitudinal dilas ku cara nerapkeun énergi listrik kana busur las.

● Las Busur Terendam (SAW): Di dieu, las dijieun ku cara ngalemberehkeun sisi-sisina kalayan busur kontinyu anu terendam dina fluks.

● Las Induksi Frékuénsi Luhur (HFI): Métode ieu ngagunakeun arus frékuénsi luhur pikeun nyieun sambungan las dina prosés anu kontinyu.

Kauntungan:

● Tahan Korosi: Tahan ka rupa-rupa média sareng lingkungan korosif.

● Kakuatan: Kakuatan mékanis anu luhur mastikeun integritas struktural.

● Serbaguna: Sadia dina rupa-rupa ukuran, kelas, sareng hasil akhir pikeun nyocogkeun kana rupa-rupa aplikasi.

● Kabersihan: Cocog pisan pikeun industri anu gaduh sarat sanitasi anu ketat.

● Awét: Némbongkeun daya tahan anu luar biasa, ngahasilkeun umur layanan anu langkung lami.

Singkatna, pipa las stainless steel mangrupikeun komponén penting di sakumna industri, nyayogikeun daya tahan, résistansi korosi, sareng versatility pikeun rupa-rupa aplikasi. Pilihan kelas anu leres, metode manufaktur, sareng patuh kana standar industri penting pisan pikeun mastikeun kinerja sareng kaamanan anu optimal tina sistem pipa las.

Spésifikasi

| ASTM A312/A312M:304, 304L, 310/S, 310H, 316, 316L, 321, 321H jsb... |

| EN 10216-5: 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 jsb... |

| DIN 17456: 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 jsb ... |

| JIS G3459: SUS304TB, SUS304LTB, SUS316TB, SUS316LTB jsb... |

| GB/T 14976: 06Cr19Ni10, 022Cr19Ni10, 06Cr17Ni12Mo2 |

| Baja tahan karat austenitik:TP304, TP304L, TP304H, TP310S, TP316, TP316L, TP316H, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H, TP347HFG N08904(904L), S30432, S31254, N08367, S30815... Baja tahan karat dupleks:S31803, S32205, S32750, S32760, S32707, S32906... Paduan NikelN04400, N06600, N06625, N08800, N08810(800H), N08825... Pamakéan:Industri minyak bumi, kimia, gas alam, tanaga listrik sareng manufaktur peralatan mékanik. |

| DN mm | NB Inci | OD mm | SCH40S mm | SCH5S mm | SCH10S mm | SCH10 mm | SCH20 mm | SCH40 mm | SCH60 mm | XS/80S mm | SCH80 mm | SCH100 mm | SCH120 mm | SCH140 mm | SCH160 mm | SCHXXS mm |

| 6 | 1/8” | 10.29 | 1.24 | 1.73 | 2.41 | |||||||||||

| 8 | 1/4” | 13.72 | 1.65 | 2.24 | 3.02 | |||||||||||

| 10 | 3/8” | 17.15 | 1.65 | 2.31 | 3.20 | |||||||||||

| 15 | 1/2” | 21.34 | 2.77 | 1.65 | 2.11 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | ||||||

| 20 | 3/4” | 26.67 | 2.87 | 1.65 | 2.11 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | ||||||

| 25 | 1” | 33.40 | 3.38 | 1.65 | 2.77 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | ||||||

| 32 | 1 1/4” | 42.16 | 3.56 | 1.65 | 2.77 | 3.56 | 4.85 | 4.85 | 6.35 | 9.70 | ||||||

| 40 | 1 1/2” | 48.26 | 3.68 | 1.65 | 2.77 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | ||||||

| 50 | 2” | 60.33 | 3.91 | 1.65 | 2.77 | 3.91 | 5.54 | 5.54 | 9.74 | 11.07 | ||||||

| 65 | 2 1/2” | 73.03 | 5.16 | 2.11 | 3.05 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | ||||||

| 80 | 3” | 88.90 | 5.49 | 2.11 | 3.05 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 | ||||||

| 90 | 3 1/2” | 101.60 | 5.74 | 2.11 | 3.05 | 5.74 | 8.08 | 8.08 | ||||||||

| 100 | 4” | 114.30 | 6.02 | 2.11 | 3.05 | 6.02 | 8.56 | 8.56 | 11.12 | 13.49 | 17.12 | |||||

| 125 | 5” | 141.30 | 6.55 | 2.77 | 3.40 | 6.55 | 9.53 | 9.53 | 12.70 | 15.88 | 19.05 | |||||

| 150 | 6 inci | 168.27 | 7.11 | 2.77 | 3.40 | 7.11 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | |||||

| 200 | 8 inci | 219.08 | 8.18 | 2.77 | 3.76 | 6.35 | 8.18 | 10.31 | 12.70 | 12.70 | 15.09 | 19.26 | 20.62 | 23.01 | 22.23 | |

| 250 | 10” | 273.05 | 9.27 | 3.40 | 4.19 | 6.35 | 9.27 | 12.70 | 12.70 | 15.09 | 19.26 | 21.44 | 25.40 | 28.58 | 25.40 | |

| 300 | 12 inci | 323.85 | 9.53 | 3.96 | 4.57 | 6.35 | 10.31 | 14.27 | 12.70 | 17.48 | 21.44 | 25.40 | 28.58 | 33.32 | 25.40 | |

| 350 | 14 inci | 355.60 | 9.53 | 3.96 | 4.78 | 6.35 | 7.92 | 11.13 | 15.09 | 12.70 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |

| 400 | 16 inci | 406.40 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 12.70 | 16.66 | 12.70 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | |

| 450 | 18 inci | 457.20 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 14.27 | 19.05 | 12.70 | 23.83 | 29.36 | 34.93 | 39.67 | 45.24 | |

| 500 | 20” | 508.00 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 | 32.54 | 38.10 | 44.45 | 50.01 | |

| 550 | 22” | 558.80 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | ||

| 600 | 24 inci | 609.60 | 9.53 | 5.54 | 6.35 | 6.35 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |

| 650 | 26 inci | 660.40 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 700 | 28 inci | 711.20 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 750 | 30” | 762.00 | 9.53 | 6.35 | 7.92 | 7.92 | 12.70 | 12.70 | ||||||||

| 800 | 32” | 812.80 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 850 | 34” | 863.60 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 900 | 36 inci | 914.40 | 9.53 | 7.92 | 12.70 | 19.05 | 12.70 | |||||||||

| DN 1000mm ka luhur Diaméter ketebalan témbok pipa tiasa disaluyukeun | ||||||||||||||||

Standar & Kelas

| Standar | Kelas Baja |

| ASTM A312/A312M: Pipa Baja Tahan Karat Austenitik Anu Mulus, Dilas, sareng Dikerjakeun Tiis Beurat | 304, 304L, 310S, 310H, 316, 316L, 321, 321H jsb... |

| ASTM A269: Pipa baja tahan karat austenitik anu mulus sareng dilas pikeun layanan umum | TP304, TP304L, TP316, TP316L, TP321, TP347 jsb... |

| ASTM A249: Boiler, Superheater, Heat-Exchanger, sareng Condenser Steel Austenitic anu dilas | 304, 304L, 316, 316L, 316H, 316N, 316LN, 317, 317L, 321, 321H, 347, 347H, 348 |

| ASTM A269: Tabung Baja Tahan Karat Diaméter Leutik Anu Mulus Sareng Dilas | 304, 304L, 316, 316L, 316H, 316N, 316LN, 317, 317L, 321, 321H, 347, 347H, 348 |

| ASTM A270: Pipa Saniter Baja Tahan Karat Austenitik sareng Feritik/Austenitik anu Mulus sareng Dilas | Kelas Baja Tahan Karat Austenitik: 304, 304L, 316, 316L, 316H, 316N, 316LN, 317, 317L, 321, 321H, 347, 347H, 348 Baja Tahan Karat Feritik/Austenitik (Dupleks) Kelas: S31803, S32205 |

| ASTM A358/A358M: Sarat Pipa Baja Austenitik Las pikeun Lingkungan Suhu Luhur, Tekanan Luhur, sareng Korosif | 304, 304L, 316, 316L, 316H, 316N, 316LN, 317, 317L, 321, 321H, 347, 347H, 348 |

| ASTM A554: Pipa mékanis baja tahan karat anu dilas, umumna dianggo pikeun aplikasi struktural atanapi hiasan | 304, 304L, 316, 316L |

| ASTM A789: Pipa baja tahan karat feritik/austenitik anu mulus sareng dilas pikeun layanan umum | S31803 (Baja tahan karat dupleks) S32205 (Baja tahan karat dupleks) |

| ASTM A790: Pipa baja tahan karat feritik/austenitik anu mulus sareng dilas pikeun layanan korosif umum, layanan suhu luhur, sareng pipa baja tahan karat dupleks. | S31803 (Baja tahan karat dupleks) S32205 (Baja tahan karat dupleks) |

| EN 10217-7: pipa baja tahan karat anu dilas sarat manufaktur Standar Éropa. | 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4003, 1.4509, 1.4510, 1.4462, 1.4948, 1.4878 jsb... |

| DIN 17457: Standar Jerman anu dianggo pikeun ngadamel pipa baja tahan karat anu dilas | 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4003, 1.4509, 1.4510, 1.4462, 1.4948, 1.4878 jsb... |

| JIS G3468: Standar Industri Jepang anu netepkeun sarat manufaktur pikeun pipa baja tahan karat anu dilas. | SUS304, SUS304L, SUS316, SUS316L, SUS329J3L jsb... |

| GB/T 12771: Standar Nasional Cina anu dianggo pikeun sarat manufaktur pipa anu dilas stainless steel. | 06Cr19Ni10, 022Cr19Ni1, 06Cr17Ni12Mo2, 022Cr22Ni5Mo3N |

| Baja tahan karat austenitik:TP304, TP304L, TP304H, TP310S, TP316, TP316L, TP316H, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H, TP347HFG N08904(904L), S30432, S31254, N08367, S30815... Baja tahan karat dupleks:S31803, S32205, S32750, S32760, S32707, S32906... Paduan Nikel:N04400, N06600, N06625, N08800, N08810(800H), N08825... Pamakéan: Industri manufaktur minyak bumi, kimia, gas alam, tanaga listrik sareng peralatan mékanik. | |

Kontrol Kualitas

Pamariksaan Bahan Baku, Analisis Kimia, Uji Mékanis, Pamariksaan Visual, Pamariksaan Diménsi, Uji Lengkungan, Uji Dampak, Uji Korosi Intergranular, Pamariksaan Non-Destruktif(UT, MT, PT) Kualifikasi Prosedur Las, Analisis Mikrostruktur, Uji Pembakaran sareng Perataan, Uji Karasa, Uji Tekanan, Uji Kandungan Ferit, Uji Metalografi, Uji Korosi, Uji Arus Eddy, Uji Semprotan Uyah, Uji Résistansi Korosi, Uji Getaran, Uji Korosi Pitting, Pamariksaan Pengecatan sareng Palapis, Tinjauan Dokuméntasi…..

Pamakéan & Aplikasi

Pipa las stainless steel seueur dianggo di sababaraha industri kusabab sipat sareng versatility anu luar biasa. Pipa-pipa ieu dianggo dina rupa-rupa aplikasi, didorong ku daya tahan, tahan korosi, sareng kasaluyuan pikeun lingkungan anu beragam. Sababaraha widang panggunaan sareng aplikasi konci pipa las stainless steel kalebet:

● Kagunaan Industri: Umum dina industri minyak, gas, petrokimia, sareng listrik kusabab tahan korosi.

● Konstruksi: Dianggo dina pipa ledeng, suplai cai, sareng struktur kusabab kakuatan sareng umurna anu panjang.

● Industri Kadaharan: Penting pisan pikeun ngangkut kadaharan sareng inuman, nyumponan standar kabersihan.

● Otomotif: Dianggo dina sistem knalpot sareng bagian struktural, tahan kana kaayaan anu sesah.

● Médis: Dianggo dina alat médis sareng pipa sanitasi, ngutamakeun kabersihan.

● Tatanén: Pikeun sistem irigasi anu tahan korosi, pikeun mastikeun distribusi cai anu efisien.

● Pangolahan Cai: Cocog pikeun ngalirkeun cai anu diolah sareng cai anu didesalinasi.

● Kelautan: Tahan kana korosi cai asin, seueur dianggo dina kapal sareng struktur lepas pantai.

● Énergi: Ngangkut cairan dina séktor énergi, kalebet gas alam sareng minyak.

● Bubur jeung Kertas: Penting pisan pikeun ngangkut bahan kimia jeung cairan dina prosés produksi.

Singkatna, pipa anu dilas tina stainless steel janten komponén penting dina rupa-rupa industri sareng aplikasi. Résistansi korosi, kakuatan mékanis, sareng kamampuan pikeun minuhan sarat anu ketat ngajantenkeun éta penting pisan pikeun infrastruktur modéren, prosés industri, sareng rupa-rupa séktor khusus.

Bungkusan & Pangiriman

Pipa baja tahan karat dibungkus sareng dikirim kalayan ati-ati pisan pikeun mastikeun panyalindunganana salami transit. Ieu pedaran ngeunaan prosés pengemasan sareng pengiriman:

Bungkusan:

● Lapisan Pelindung: Sateuacan dibungkus, pipa stainless steel sering dilapis ku lapisan minyak pelindung atanapi film pikeun nyegah korosi sareng karusakan permukaan.

● Bundelan: Pipa anu ukuran sareng spésifikasina sami dibundel sacara saksama. Éta pipa diiket nganggo tali, atanapi pita plastik pikeun nyegah gerakan dina bundelan.

● Tutup Tungtung: Tutup tungtung plastik atanapi logam disimpen dina dua tungtung pipa pikeun masihan panyalindungan tambahan kana tungtung sareng ulir pipa.

● Bantalan jeung Empuk: Bahan bantalan saperti busa, bungkus gelembung, atawa kardus bergelombang dipaké pikeun nyadiakeun bantalan jeung nyegah karusakan akibat tabrakan nalika diangkut.

● Peti atawa Wadah Kai: Dina sababaraha kasus, pipa bisa dipak dina peti atawa wadah kai pikeun méré panyalindungan tambahan tina gaya jeung penanganan éksternal.

Balanja:

● Moda Transportasi: Pipa stainless steel biasana dikirim nganggo rupa-rupa moda transportasi sapertos treuk, kapal, atanapi angkutan udara, gumantung kana tujuan sareng urgensina.

● Kontainerisasi: Pipa tiasa dimuat kana kontainer pengiriman pikeun mastikeun transit anu aman sareng teratur. Ieu ogé nawiskeun panyalindungan tina kaayaan cuaca sareng kontaminan éksternal.

● Labél sareng Dokuméntasi: Unggal pakét dilabélan ku inpormasi penting, kalebet spésifikasi, kuantitas, pitunjuk penanganan, sareng detil tujuan. Dokumén pengiriman disiapkeun pikeun bea cukai sareng pelacakan.

● Patuh kana Pabean: Pikeun kiriman internasional, sadaya dokuméntasi bea cukai anu diperyogikeun disiapkeun pikeun mastikeun kalancaran pangiriman di tempat tujuan.

● Pangiket anu Aman: Dina kandaraan atanapi wadah transportasi, pipa-pipa dipasang kalayan aman pikeun nyegah gerakan sareng ngaminimalkeun résiko karusakan nalika transit.

● Pelacakan sareng Pemantauan: Sistem pelacakan canggih tiasa dianggo pikeun ngawas lokasi sareng kaayaan kiriman sacara real-time.

● Asuransi: Gumantung kana nilai kargo, asuransi pengiriman tiasa diala pikeun nutupan poténsi karugian atanapi karusakan salami transit.

Singkatna, pipa stainless steel anu kami hasilkeun bakal dibungkus nganggo ukuran pelindung sareng dikirim nganggo metode transportasi anu tiasa dipercaya pikeun mastikeun aranjeunna dugi ka tujuan dina kaayaan anu optimal. Prosedur pengemasan sareng pengiriman anu leres nyumbang kana integritas sareng kualitas pipa anu dikirimkeun.