Panjelasan Produk

Casing sareng pipah seueur dianggo pikeun minyak sareng gas berkembang, Casing sareng pipah mangrupikeun komponén penting dina industri minyak sareng gas anu dianggo pikeun ékstraksi sareng transportasi hidrokarbon (minyak sareng gas alam) tina waduk bawah tanah ka permukaan. Aranjeunna maénkeun peran anu penting dina mastikeun kasalametan, integritas, sareng efisiensi operasi pangeboran sareng produksi.

Tubing mangrupikeun jinis pipa anu dianggo pikeun mindahkeun minyak bumi sareng gas alam tina lapisan minyak atanapi lapisan gas kana taneuh saatos pangeboran réngsé. Tubing tiasa ngamungkinkeun tekanan anu dibangkitkeun nalika prosés ékstraksi. Tubing dihasilkeun dina cara nu sarua salaku casing, tapi prosés nu disebut "upsetting" ieu Sajaba diperlukeun pikeun thicken pipa tubing.

Casing dipaké pikeun ngajaga liang bor anu geus digali kana taneuh pikeun minyak. Dipaké sarua jeung pipa bor, pipa casing sumur minyak ogé ngidinan tekanan tegangan axial, jadi kualitas luhur-kakuatan baja diperlukeun. OCTG casings mangrupakeun pipa diaméterna badag nu cemented kana borehole nu.

spésifikasi

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| API 5D: E75, X95, G105, S135 |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A106: GR.A, GR.B, GR.C |

| ASTM A53/A53M: GR.A, GR.B |

| ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 |

| ASTM A333: Gr.1, Gr.3, Gr.4, Gr.6, Gr.7, Gr.8, Gr.9.Gr.10, Gr.11 |

| DIN 2391: St30Al, St30Si, St35, St45, St52 |

| DIN EN 10216-1: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| JIS G3454: STPG 370, STPG 410 |

| JIS G3456: STPT 370, STPT 410, STPT 480 |

| GB / T 8163: 10 #, 20 #, Q345 |

| GB/T 8162: 10#, 20#, 35#, 45#, Q345 |

ISO / API Steel Casing daptar

| Labelsa | Di luar diaméterna D mm | Nominal liniér jisimb, c T&C kg/m | Tembok kandelna t mm | Jenis tungtung-finish | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Tipe 1, Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 | 9.50 10.50 11.60 13.50 15.10 | 114,30 114,30 114,30 114,30 114,30 | 14,14 15,63 17,26 20,09 22,47 | 5,21 5,69 6,35 7,37 8,56 | PS — — — — | PS PSB PSLB — — | PS PSB PLB PLB — | — — PLB PLB — | — — PLB PLB — | — — PLB PLB — | — — PLB PLB PLB | — — — — PLB |

| 5 5 5 5 5 5 5 | 11.50 13.00 15.00 18.00 21.40 23.20 24.10 | 127,00 127,00 127,00 127,00 127,00 127,00 127,00 | 17,11 19,35 22,32 26,79 31,85 34,53 35,86 | 5,59 6,43 7,52 9,19 11,10 12,14 12,70 | — — — — — — — | PS PSLB PSLBE — — — — | PS PSLB PLB PLB PLB — — | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — — PLBE PLB PLB PLB |

| 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 | 14.00 15.50 17.00 20.00 23.00 26.80 29.70 32.60 35.30 38.00 40.50 43.10 | 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 | 20,83 23,07 25,30 29,76 34,23 39,88 44,20 48,51 52,53 56,55 60,27 64,14 | 6,20 6,98 7,72 9,17 10,54 12,70 14,27 15,88 17,45 19,05 20,62 22,22 | PS | PS PSLBE PSLBE | PS PSLB PLB PLB PLB | — — PLBE PLBE PLBE — — — — — — — | PLBE PLBE PLBE | PLBE PLBE PLBE P P P P P P P | PLBE PLBE PLBE | — — — — PLBE — — — — — — |

| 6-5/8 6-5/8 6-5/8 6-5/8 | 20.00 24.00 28.00 32.00 | 168,28 168,28 168,28 168,28 | 29,76 35,72 41,67 47,62 | 7,32 8,94 10,59 12,06 | PS — — | PSLB PSLBE — | PSLB PLB PLB — | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — — PLBE |

| 7 7 7 7 7 7 7 7 7 7 7 7 7 | 17.00 20.00 23.00 26.00 29.00 32.00 35.00 38.00 42.70 46.40 50.10 53.60 57.10 | 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 | 25,30 29,76 34,23 38,69 43,16 47,62 52,09 56,55 63,54 69,05 74,56 79,77 84,97 | 5,87 6,91 8,05 9,19 10,36 11,51 12,65 13,72 15,88 17,45 19,05 20,62 22,22 | PS PS — — — — — — — — — — — | — PS PSLBE PSLBE — — — — — — — — — | — PS PLB PLB PLB PLB — — — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE P P P P P | — — — PLBE PLBE PLBE PLBE PLBE — — — — — | — — — — — — PLBE PLBE — — — — — |

| Tingali catetan dina tungtung méja. | ||||||||||||

| Labelsa | Di luar diaméterna D mm | Nominal liniér jisimb, c T&C kg/m | Tembok kandelna t mm | Jenis tungtung-finish | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Tipe 1, Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 | 24.00 26.40 29.70 33.70 39.00 42.80 45.30 47.10 51.20 55.30 | 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 | 35,72 39,29 44,20 50,15 58,04 63,69 67,41 70,09 76,19 82,30 | 7,62 8,33 9,52 10,92 12,70 14,27 15,11 15,88 17,45 19,05 | PS | PSLBE | PSLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB P P | PLBE PLBE PLBE PLB PLB PLB | PLBE PLB PLB PLB |

| 7-3/4 | 46.10 | 19.685 | 6.860 | 1.511 | — | — | — | P | P | P | P | P |

| 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 | 24.00 28.00 32.00 36.00 40.00 44.00 49.00 | 219,08 219,08 219,08 219,08 219,08 219,08 219,08 | 35,72 41,67 47,62 53,57 59,53 65,48 72,92 | 6,71 7,72 8,94 10,16 11,43 12,70 14,15 | PS PS — — — — | PS — PSLBE PSLBE — — — | PS PS PSLB PSLB PLB — — | — — — PLBE PLBE PLBE PLBE | — — — PLBE PLBE PLBE PLBE | — — — PLBE PLBE PLBE PLBE | — — — — PLBE PLBE PLBE | — — — — — — PLBE |

| 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 | 32.30 36.00 40.00 43.50 47.00 53.50 58.40 59.40 64.90 70.30 75.60 | 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 | 48,07 53,57 59,53 64,73 69,94 79,62 86,91 88,40 96,58 104,62 112,50 | 7,92 8,94 10,03 11,05 11,99 13,84 15,11 15,47 17,07 18,64 20,24 | PS PS — — — — — — — — — | — PSLB PSLBE — — — — — — — — | — PSLB PSLB PLB PLB — — — — — — | — — PLBE PLBE PLBE PLBE PLB — — — — | — — PLBE PLBE PLBE PLBE PLB — — — — | — — PLBE PLBE PLBE PLBE PLB P P P P | — — — PLBE PLBE PLBE PLB — — — — | — — — — PLBE PLBE PLB — — — — |

| 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 | 32.75 40.50 45.50 51.00 55.50 60.70 65.70 73.20 79.20 85.30 | 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 | 48,74 60,27 67,71 75,90 82,59 90,33 97,77 108,93 117,86 126,94 | 7,09 8,89 10,16 11,43 12,57 13,84 15,11 17,07 18,64 20,24 | PS PS | PSB PSBE PSBE | PSB PSB PSB PSB | PSBE PSBE | PSBE PSBE | PSBE PSBE PSBE PSB P P P | PSBE PSBE PSBE PSB | PSBE PSB |

| 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 | 42.00 47.00 54.00 60.00 65.00 71.00 | 298,45 298,45 298,45 298,45 298,45 298,45 | 62,50 69,94 80,36 89,29 96,73 105,66 | 8,46 9,53 11,05 12,42 13,56 14,78 | PS — — — | PSB PSB PSB — — | PSB PSB PSB — — | — — PSB P P | — — PSB P P | — — PSB P P | — — PSB P P | — — PSB P P |

| 13-3/8 13-3/8 13-3/8 13-3/8 13-3/8 | 48.00 54.50 61.00 68.00 72.00 | 339,72 339,72 339,72 339,72 339,72 | 71,43 81,10 90,78 101,19 107,15 | 8,38 9,65 10,92 12,19 13,06 | PS — — — — | — PSB PSB PSB — | — PSB PSB PSB — | — — — PSB PSB | — — — PSB PSB | — — — PSB PSB | — — — PSB PSB | — — — — PSB |

| Tingali catetan dina tungtung méja. | ||||||||||||

| Labelsa | Di luar diaméterna D mm | Nominal liniér jisimb, c T&C kg/m | Tembok kandelna t mm | Jenis tungtung-finish | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Tipe 1, Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 16 16 16 16 | 65.00 75.00 84.00 109.00 | 406,40 406,40 406,40 406,40 | 96,73 111,61 125,01 162,21 | 9,53 11,13 12,57 16,66 | PS | PSB PSB P | PSB PSB | P | P | P | P | |

| 18-5/8 | 87.50 | 47.308 | 13.021 | 1.105 | PS | PSB | PSB | — | — | — | — | — |

| 20 20 20 | 94.00 106.50 133.00 | 508,00 508,00 508,00 | 139,89 158,49 197,93 | 11,13 12,70 16,13 | PSL — — | PSLB PSLB PSLB | PSLB PSLB — | — — — | — — — | — — — | — — — | — — — |

| P = Tungtung polos, S = Benang buleud pondok, L = Benang buleud panjang, B = Benang buttress, E = Garis ekstrim. | ||||||||||||

| ♦ Label kanggo inpormasi sareng bantosan dina mesen. ♦ Nominal massa linier, threaded jeung gandeng (col. 2) dipintonkeun pikeun informasi wungkul. ♦ Kapadetan baja kromium martensit (tipe L80 9Cr sareng 13Cr) béda sareng baja karbon. Beurat anu ditingalikeun henteu akurat pikeun baja kromium martensit. Faktor koreksi massa 0,989 tiasa dianggo. | ||||||||||||

| Labels | Diaméter luar D mm | Linear polos-tungtung jisim kg/m | Kandel témbok t mm | |

| 1 | 2 | |||

| 1 | 2 | 3 | 4 | 5 |

| 3-1/2 4 4-1/2 5 5-1/2 6-5/8 | 9.92 11.35 13.05 17.95 19.83 27.66 | 88,90 101,60 114,30 127,00 139,70 168,28 | 14,76 16,89 19,42 26,71 29,51 41,18 | 7,34 7,26 7,37 9,19 9,17 10,59 |

ISO / API Steel Tubing daptar

| Labels | Di luar diaméterna D mm | liniér nominal massaa, b | Tembok kandel- ness t mm | Jenis tungtung tungtungc | |||||||||||

| non- kesel T&C kg/m | Ext. kesel T&C kg/m | Integ. gabungan kg/m | |||||||||||||

| 1 | 2 | ||||||||||||||

| NU T&C | EU T&C | IJ | H40 | J55 | L80 | N80 Tipe 1, Q | C90 | T95 | P110 | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1.900 1.900 1.900 1.900 1.900 | 2.40 2.75 3.65 4.42 5.15 | — 2.90 3.73 — — | 2.40 2.76 — — — | 48,26 48,26 48,26 48,26 48,26 | — 4,09 5,43 6,58 7,66 | — 4,32 5,55 — — | 3,57 4,11 — — — | 3,18 3,68 5,08 6,35 7,62 | PI PNUI PU — — | PI PNUI PU — — | — PNUI PU P P | — PNUI PU — — | — PNUI PU P P | — PNUI PU P P | PU — — |

| 2.063 2.063 | 3.24 4.50 | — — | 3.25 — | 52,40 52,40 | — — | — — | 4,84 — | 3,96 5,72 | PI P | PI P | PI P | PI P | PI P | PI P | P |

| 2-3/8 2-3/8 2-3/8 2-3/8 2-3/8 | 4.00 4.60 5.80 6.60 7.35 | 4.70 5.95 7.45 | 60,32 60,32 60,32 60,32 60,32 | 5,95 6,85 8,63 9,82 10,94 | 6,99 8,85 11,09 | 4,24 4,83 6,45 7,49 8,53 | PN PNU | PN PNU | PN PNU PNU P PU | PN PNU PNU — — | PN PNU PNU P PU | PN PNU PNU P PU | PNU PNU | ||

| 2-7/8 2-7/8 2-7/8 2-7/8 | 6.40 7.80 8.60 9.35 | 6.50 7.90 8.70 9.45 | — — — | 73,02 73,02 73,02 73,02 | 9,52 11,61 12,80 13,91 | 9,67 11,76 12,95 14,06 | — — — | 5,51 7,01 7,82 8,64 | PNU — — | PNU — — | PNU PNU PNU PU | PNU PNU PNU — | PNU PNU PNU PU | PNU PNU PNU PU | PNU PNU PNU — |

| 2-7/8 2-7/8 | 10.50 11.50 | — | — | 73,02 73,02 | 15,63 17,11 | — | — | 9,96 11,18 | — | — | P P | — | P P | P P | — |

| 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 | 7.70 9.20 10.20 12.70 14.30 15.50 17.00 | — 9.30 — 12.95 — — — | — — — — — — — | 88,90 88,90 88,90 88,90 88,90 88,90 88,90 | 11,46 13,69 15,18 18,90 21,28 23,07 25,30 | — 13,84 — 19,27 — — — | — — — — — — — | 5,49 6,45 7,34 9,52 10,92 12,09 13,46 | PN PNU PN — — — — | PN PNU PN — — — — | PN PNU PN PNU P P P | PN PNU PN PNU — — — | PN PNU PN PNU P P P | PN PNU PN PNU P P P | — PNU — PNU — — — |

| 4 4 4 4 4 4 | 9.50 10.70 13.20 16.10 18.90 22.20 | — 11.00 — — — — | — — — — — — | 101,60 101,60 101,60 101,60 101,60 101,60 | 14,14 — 19,64 23,96 28,13 33,04 | — 16,37 — — — — | — — — — — — | 5,74 6,65 8,38 10,54 12,70 15,49 | PN PU — — — — | PN PU — — — — | PN PU P P P P | PN PU — — — — | PN PU P P P P | PN PU P P P P | — — — — — — |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 | 12.60 15.20 17.00 18.90 21.50 23.70 26.10 | 12.75 | 114,30 114,30 114,30 114,30 114,30 114,30 114,30 | 18,75 22,62 25,30 28,13 32,00 35,27 38,84 | 18,97 | 6,88 8,56 9,65 10,92 12,70 14,22 16,00 | PNU | PNU | PNU P P P P P P | PNU — — — — — — | PNU P P P P P P | PNU P P P P P P | |||

| P = Tungtung polos, N = Non-kesel threaded na gandeng, U = kesel éksternal threaded na gandeng, I = Integral gabungan. | |||||||||||||||

| ♦ Massa linier nominal, benang sareng gandeng (col. 2, 3, 4) dipidangkeun kanggo inpormasi wungkul. ♦ Kapadetan baja kromium martensit (tipe L80 9Cr sareng 13Cr) béda sareng baja karbon. Beurat anu ditingalikeun henteu akurat pikeun baja kromium martensit. Faktor koreksi massa 0,989 tiasa dianggo. ♦ Non-kesel tubing geus sadia kalawan couplings biasa atawa couplings bevel husus. Pipa kesel éksternal sayogi nganggo kopling biasa, bevel khusus, atanapi kopling clearance khusus. | |||||||||||||||

Standar & Kelas

Casing sareng tubing Kelas Standar:

API 5CT J55, K55, L80, N80, P110, C90, T95, H40

API 5CT casing na tubing pipe tungtung:

(STC)Kasing benang buleud pondok

(LC) Casing benang buleud panjang

(BC)Casing benang buttress

(XC)Casing garis ekstrim

(NU)Tubing non-kesel

(EU) Pipa kesel éksternal

(IJ) Tubing gabungan integral

The casing na tubing kedah pangiriman nurutkeun luhur sambungan kalawan standar API5CT / API Standards.

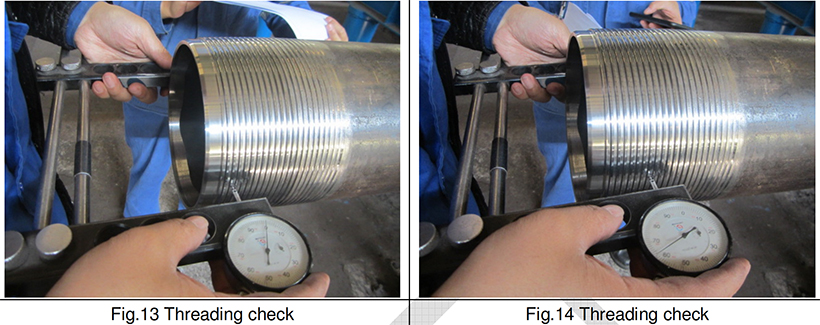

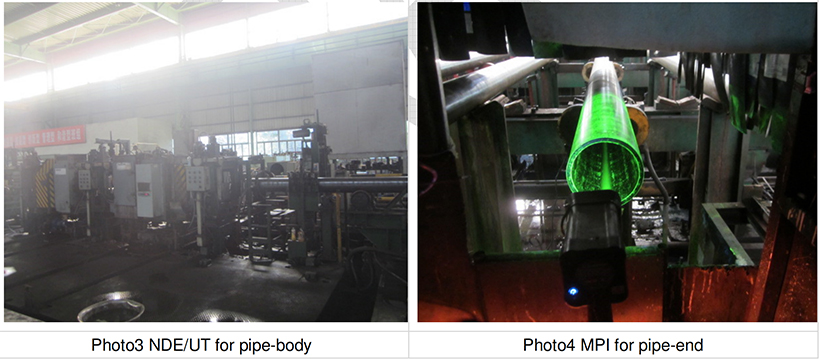

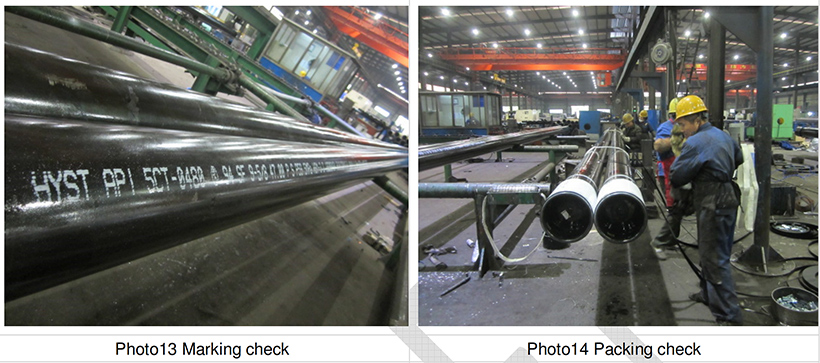

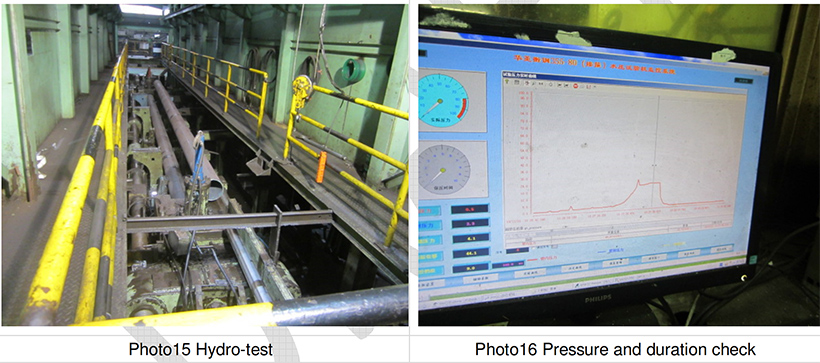

Kontrol kualitas

Mariksa Bahan Baku, Analisis Kimia, Uji Mékanis, Inspeksi Visual, Uji Tegangan, Mariksa Dimensi, Uji Bend, Uji Flattening, Uji Dampak, Uji DWT, Uji NDT, Uji Hidrostatik, Uji Kakerasan… ..

Nyirian, Lukisan saméméh pangiriman.

Bungkusan & Pangiriman

Metodeu bungkusan pikeun pipa baja ngalibatkeun beberesih, ngagolongkeun, wrapping, bundling, securing, labél, palletizing (lamun perlu), containerization, stowing, sealing, transportasi, jeung unpacking. Jenis béda tina pipa baja jeung fittings kalawan métode packing béda. Prosés komprehensif ieu ensures yén pipa baja pengiriman barang sarta anjog ka tujuan maranéhanana dina kaayaan optimal, siap pikeun pamakéan dimaksudkeun maranéhanana.

Pamakéan & Aplikasi

Pipa baja janten tulang tonggong tina rékayasa industri sareng sipil modéren, ngadukung rupa-rupa aplikasi anu nyumbang kana pangwangunan masarakat sareng ékonomi di sakuliah dunya.

Pipa baja sareng fittings kami Womic Steel dihasilkeun loba dipaké pikeun minyak bumi, gas, suluh & pipa cai, lepas pantai / darat, proyék konstruksi port laut & wangunan, pangerukan, Steel struktural, tumpukan jeung proyék konstruksi sasak, ogé tabung baja precision pikeun conveyor roller produksi, jsb ...