Panjelasan Produk

Pipa baja spiral, ogé katelah pipa helical submerged arc-welded (HSAW), nyaéta jinis pipa baja anu dicirikeun ku prosés manufaktur sareng sipat struktural anu khas. Pipa-pipa ieu seueur dianggo dina rupa-rupa industri kusabab kakuatan, daya tahan, sareng adaptasina. Ieu pedaran lengkep ngeunaan pipa baja spiral:

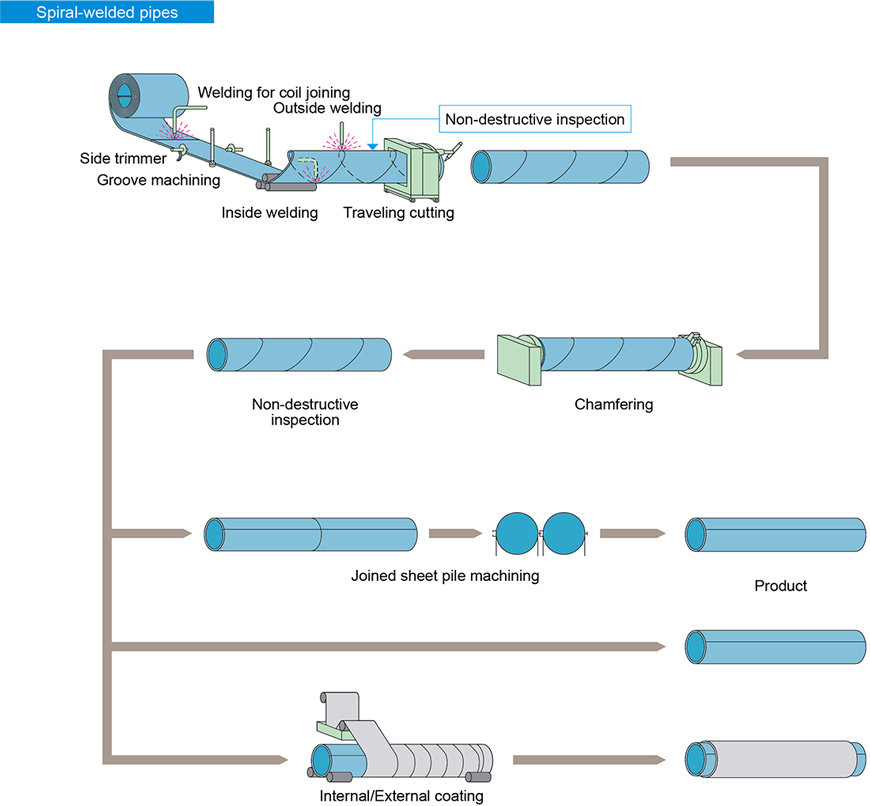

Prosés Manufaktur:Pipa baja spiral dihasilkeun ngaliwatan prosés unik anu ngalibatkeun panggunaan gulungan strip baja. Strip ieu dileupaskeun sareng dibentuk janten bentuk spiral, teras dilas nganggo téknik las busur submerged (SAW). Prosés ieu ngahasilkeun jahitan heliks anu kontinyu sapanjang pipa.

Desain Struktural:Jahitan heliks tina pipa baja spiral nyadiakeun kakuatan anu aya dina dirina, ngajantenkeun éta cocog pikeun nahan beban sareng tekanan anu luhur. Desain ieu mastikeun distribusi tegangan anu seragam sareng ningkatkeun kamampuan pipa pikeun nolak lenturan sareng deformasi.

Rentang Ukuran:Pipa baja spiral hadir dina rupa-rupa diaméter (dugi ka 120 inci) sareng ketebalan, anu ngamungkinkeun kalenturan dina rupa-rupa aplikasi. Pipa ieu umumna sayogi dina diaméter anu langkung ageung dibandingkeun sareng jinis pipa anu sanés.

Aplikasi:Pipa baja spiral dianggo dina rupa-rupa industri sapertos minyak sareng gas, suplai cai, konstruksi, tatanén, sareng pamekaran infrastruktur. Éta cocog pikeun aplikasi di luhur taneuh sareng di handapeun taneuh.

Résistansi Korosi:Pikeun ningkatkeun umur panjang, pipa baja spiral sering ngalaman perawatan anti korosi. Ieu tiasa kalebet palapis internal sareng éksternal, sapertos epoksi, polietilen, sareng séng, anu ngajaga pipa tina unsur lingkungan sareng zat korosif.

Kauntungan:Pipa baja spiral nawiskeun sababaraha kaunggulan, kalebet kapasitas nahan beban anu luhur, efektivitas biaya pikeun pipa diaméter ageung, gampang dipasang, sareng tahan kana deformasi. Desain heliksna ogé ngabantosan drainase anu efisien.

BujurVSSpiral:Pipa baja spiral bisa dibédakeun ti pipa anu dilas sacara longitudinal dumasar kana prosés manufakturna. Sanaos pipa longitudinal dibentuk sareng dilas sapanjang pipa, pipa spiral ngagaduhan jahitan heliks anu kabentuk nalika manufaktur.

Kontrol Kualitas:Prosés manufaktur sareng kontrol kualitas penting pisan dina ngahasilkeun pipa baja spiral anu tiasa dipercaya. Parameter pengelasan, géométri pipa, sareng metode uji diawasi sacara saksama pikeun mastikeun patuh kana standar sareng spésifikasi industri.

Standar sareng Spésifikasi:Pipa baja spiral dijieun luyu jeung standar internasional jeung industri husus saperti API 5L, ASTM, EN, jeung sajabana. Standar ieu ngahartikeun sipat bahan, métode manufaktur, jeung sarat uji.

Singkatna, pipa baja spiral mangrupikeun solusi anu serbaguna sareng awét pikeun rupa-rupa industri. Prosés manufaktur anu unik, kakuatan anu aya, sareng kasadiaan dina ukuran anu béda-béda nyumbang kana panggunaan anu lega dina infrastruktur, transportasi, énergi, konstruksi palabuhan sareng seueur deui. Pilihan anu leres, kontrol kualitas, sareng ukuran panyalindungan korosi maénkeun peran penting dina mastikeun kinerja jangka panjang pipa baja spiral.

Spésifikasi

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A252: GR.1, GR.2, GR.3 |

| EN 10219-1: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: GR.A, GR.B |

| EN 10217: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| DIN 2458: St37.0, St44.0, St52.0 |

| AS/NZS 1163: Kelas C250, Kelas C350, Kelas C450 |

| GB/T 9711: L175, L210, L245, L290, L320, L360, L390, L415, L450, L485 |

| ASTMA671: CA55/CB70/CC65, CB60/CB65/CB70/CC60/CC70, CD70/CE55/CE65/CF65/CF70, CF66/CF71/CF72/CF73, CG100/CH100/CI100/CJ100 |

| Diaméter (mm) | Kandel Témbok (mm) | |||||||||||||||||||

| 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | |

| 219.1 | ● | ● | ● | ● | ||||||||||||||||

| 273 | ● | ● | ● | ● | ● | |||||||||||||||

| 323.9 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 325 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 355.6 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 377 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 406.4 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 426 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 457 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 478 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 508 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 529 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 630 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| 711 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 720 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 813 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

| 820 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

| 920 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 1020 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 1220 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 1420 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 1620 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| 1820 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 2020 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 2220 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 2500 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 2540 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 3000 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

Toleransi Diaméter Luar sareng Kandel Témbok

| Standar | Toleransi Awak Pipa | Toleransi Tungtung Pipa | Toleransi Kandel Tembok | |||

| Diaméter Luar | Toleransi | Diaméter Luar | Toleransi | |||

| GB/T3091 | OD≤48.3mm | ≤±0.5 | OD≤48.3mm | - | ≤±10% | |

| 48.3 | ≤±1.0% | 48.3 | - | |||

| 273.1 | ≤±0,75% | 273.1 | -0.8~+2.4 | |||

| OD>508mm | ≤±1.0% | OD>508mm | -0.8~+3.2 | |||

| GB/T9711.1 | OD≤48.3mm | -0.79~+0.41 | - | - | OD≤73 | -12,5%~+20% |

| 60.3 | ≤±0,75% | OD≤273.1mm | -0.4~+1.59 | 88.9≤OD≤457 | -12,5%~+15% | |

| 508 | ≤±1.0% | OD≥323.9 | -0.79~+2.38 | OD≥508 | -10.0%~+17.5% | |

| OD>941mm | ≤±1.0% | - | - | - | - | |

| GB/T9711.2 | 60 | ±0,75%D~±3mm | 60 | ±0.5%D~±1.6mm | 4mm | ±12,5%T ~ ±15,0%T |

| 610 | ±0.5%D~±4mm | 610 | ±0.5%D~±1.6mm | Beurat awak ≥25mm | -3.00mm~+3.75mm | |

| OD>1430mm | - | OD>1430mm | - | - | -10.0%~+17.5% | |

| SY/T5037 | OD<508mm | ≤±0,75% | OD<508mm | ≤±0,75% | OD<508mm | ≤±12,5% |

| OD≥508mm | ≤±1.00% | OD≥508mm | ≤±0,50% | OD≥508mm | ≤±10.0% | |

| API 5L PSL1/PSL2 | OD <60.3 | -0.8mm~+0.4mm | OD≤168.3 | -0.4mm~+1.6mm | Beurat awak ≤5.0 | ≤±0.5 |

| 60.3≤OD≤168.3 | ≤±0,75% | 168.3 | ≤±1.6mm | 5.0 | ≤±0.1T | |

| 168.3 | ≤±0,75% | 610 | ≤±1.6mm | T≥15.0 | ≤±1.5 | |

| 610 | ≤±4.0mm | OD>1422 | - | - | - | |

| OD>1422 | - | - | - | - | - | |

| API 5CT | OD <114.3 | ≤±0.79mm | OD <114.3 | ≤±0.79mm | ≤-12,5% | |

| OD≥114.3 | -0,5% ~ 1,0% | OD≥114.3 | -0,5% ~ 1,0% | ≤-12,5% | ||

| ASTM A53 | ≤±1.0% | ≤±1.0% | ≤-12,5% | |||

| ASTM A252 | ≤±1.0% | ≤±1.0% | ≤-12,5% | |||

| DN mm | NB Inci | OD mm | SCH40S mm | SCH5S mm | SCH10S mm | SCH10 mm | SCH20 mm | SCH40 mm | SCH60 mm | XS/80S mm | SCH80 mm | SCH100 mm | SCH120 mm | SCH140 mm | SCH160 mm | SCHXXS mm |

| 6 | 1/8” | 10.29 | 1.24 | 1.73 | 2.41 | |||||||||||

| 8 | 1/4” | 13.72 | 1.65 | 2.24 | 3.02 | |||||||||||

| 10 | 3/8” | 17.15 | 1.65 | 2.31 | 3.20 | |||||||||||

| 15 | 1/2” | 21.34 | 2.77 | 1.65 | 2.11 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | ||||||

| 20 | 3/4” | 26.67 | 2.87 | 1.65 | 2.11 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | ||||||

| 25 | 1” | 33.40 | 3.38 | 1.65 | 2.77 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | ||||||

| 32 | 1 1/4” | 42.16 | 3.56 | 1.65 | 2.77 | 3.56 | 4.85 | 4.85 | 6.35 | 9.70 | ||||||

| 40 | 1 1/2” | 48.26 | 3.68 | 1.65 | 2.77 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | ||||||

| 50 | 2” | 60.33 | 3.91 | 1.65 | 2.77 | 3.91 | 5.54 | 5.54 | 9.74 | 11.07 | ||||||

| 65 | 2 1/2” | 73.03 | 5.16 | 2.11 | 3.05 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | ||||||

| 80 | 3” | 88.90 | 5.49 | 2.11 | 3.05 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 | ||||||

| 90 | 3 1/2” | 101.60 | 5.74 | 2.11 | 3.05 | 5.74 | 8.08 | 8.08 | ||||||||

| 100 | 4” | 114.30 | 6.02 | 2.11 | 3.05 | 6.02 | 8.56 | 8.56 | 11.12 | 13.49 | 17.12 | |||||

| 125 | 5” | 141.30 | 6.55 | 2.77 | 3.40 | 6.55 | 9.53 | 9.53 | 12.70 | 15.88 | 19.05 | |||||

| 150 | 6 inci | 168.27 | 7.11 | 2.77 | 3.40 | 7.11 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | |||||

| 200 | 8 inci | 219.08 | 8.18 | 2.77 | 3.76 | 6.35 | 8.18 | 10.31 | 12.70 | 12.70 | 15.09 | 19.26 | 20.62 | 23.01 | 22.23 | |

| 250 | 10” | 273.05 | 9.27 | 3.40 | 4.19 | 6.35 | 9.27 | 12.70 | 12.70 | 15.09 | 19.26 | 21.44 | 25.40 | 28.58 | 25.40 | |

| 300 | 12 inci | 323.85 | 9.53 | 3.96 | 4.57 | 6.35 | 10.31 | 14.27 | 12.70 | 17.48 | 21.44 | 25.40 | 28.58 | 33.32 | 25.40 | |

| 350 | 14 inci | 355.60 | 9.53 | 3.96 | 4.78 | 6.35 | 7.92 | 11.13 | 15.09 | 12.70 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |

| 400 | 16 inci | 406.40 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 12.70 | 16.66 | 12.70 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | |

| 450 | 18 inci | 457.20 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 14.27 | 19.05 | 12.70 | 23.83 | 29.36 | 34.93 | 39.67 | 45.24 | |

| 500 | 20” | 508.00 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 | 32.54 | 38.10 | 44.45 | 50.01 | |

| 550 | 22” | 558.80 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | ||

| 600 | 24 inci | 609.60 | 9.53 | 5.54 | 6.35 | 6.35 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |

| 650 | 26 inci | 660.40 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 700 | 28 inci | 711.20 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 750 | 30” | 762.00 | 9.53 | 6.35 | 7.92 | 7.92 | 12.70 | 12.70 | ||||||||

| 800 | 32” | 812.80 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 850 | 34” | 863.60 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 900 | 36 inci | 914.40 | 9.53 | 7.92 | 12.70 | 19.05 | 12.70 | |||||||||

| DN 1000mm ka luhur Diaméter ketebalan témbok pipa Maksimum 25mm | ||||||||||||||||

Standar & Kelas

| Standar | Kelas Baja |

| API 5L: Spésifikasi pikeun Pipa Jalur | GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A252: Spésifikasi Standar pikeun Tumpukan Pipa Baja anu Dilas sareng Seamless | GR.1, GR.2, GR.3 |

| EN 10219-1: Bagian Kosong Struktural Las Tiis tina Baja Non-paduan sareng Baja Serat Halus | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: Bagian Kosong Struktural Rengse Panas tina Baja Non-Paduan sareng Baja Serat Halus | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: Pipa, Baja, Hideung sareng Dicelup Panas, Dilapis Seng, Dilas sareng Mulus | GR.A, GR.B |

| EN 10217: Tabung Baja anu Dilas pikeun Tujuan Tekanan | P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| DIN 2458: Pipa sareng Tabung Baja anu Dilas | St37.0, St44.0, St52.0 |

| AS/NZS 1163: Standar Australia/Selandia Baru pikeun Bagian Berongga Baja Struktural anu Dibentuk Tiis | Kelas C250, Kelas C350, Kelas C450 |

| GB/T 9711: Industri Perminyakan sareng Gas Alam - Pipa Baja pikeun Pipa | L175, L210, L245, L290, L320, L360, L390, L415, L450, L485 |

| AWWA C200: Pipa Cai Baja 6 Inci (150 mm) sareng Anu Langkung Ageung | Baja Karbon |

Prosés Manufaktur

Kontrol Kualitas

● Pamariksaan Bahan Baku

● Analisis Kimia

● Tés Mékanis

● Inspeksi Visual

● Pamariksaan Diménsi

● Tés Lengkungan

● Uji Dampak

● Uji Korosi Intergranular

● Pamariksaan Non-Destruktif (UT, MT, PT)

● Kualifikasi Prosedur Las

● Analisis Mikrostruktur

● Uji Ngalembereh jeung Ngaratakeun

● Uji Karasa

● Uji Tekanan

● Uji Metalografi

● Uji Korosi

● Uji Arus Eddy

● Inspeksi Pengecatan sareng Pelapis

● Tinjauan Dokuméntasi

Pamakéan & Aplikasi

Pipa baja spiral serbaguna sareng seueur dianggo dina rupa-rupa industri kusabab ciri sareng kaunggulanana anu unik. Éta dibentuk ku cara ngelas las baja sacara heliks pikeun ngadamel pipa kalayan sambungan spiral anu kontinyu. Ieu sababaraha aplikasi umum tina pipa baja spiral:

● Angkutan Cairan: Pipa-pipa ieu sacara efisien mindahkeun cai, minyak, sareng gas dina jarak anu jauh dina pipa kusabab konstruksina anu mulus sareng kakuatan anu luhur.

● Minyak sareng Gas: Penting pisan pikeun industri minyak sareng gas, aranjeunna ngangkut minyak mentah, gas alam, sareng produk olahan, ngalayanan kabutuhan éksplorasi sareng distribusi.

● Pancang: Pancang pondasi dina proyék konstruksi nahan beban beurat dina struktur sapertos gedong sareng sasak.

● Kagunaan Struktural: Dianggo dina rangka wangunan, kolom, sareng pangrojong, daya tahanna nyumbang kana stabilitas struktural.

● Gorong-gorong jeung Drainase: Dianggo dina sistem cai, tahan korosi jeung interiorna anu mulus nyegah panyumbatan sarta ningkatkeun aliran cai.

● Pipa Mékanis: Dina manufaktur sareng tatanén, pipa ieu nyayogikeun solusi anu hemat biaya sareng kokoh pikeun komponén.

● Kelautan sareng Lepas Pantai: Pikeun lingkungan anu keras, ieu dianggo dina pipa handapeun cai, platform lepas pantai, sareng konstruksi dermaga.

● Pertambangan: Aranjeunna ngangkut bahan sareng bubur dina operasi pertambangan anu nungtut kusabab konstruksina anu kuat.

● Pasokan Cai: Ideal pikeun pipa diaméter ageung dina sistem cai, anu sacara efisien ngangkut volume cai anu ageung.

● Sistem Panas Bumi: Dianggo dina proyék énergi panas bumi, sistem ieu ngatur transfer cairan anu tahan panas antara waduk sareng pembangkit listrik.

Sifat pipa baja spiral anu serbaguna, digabungkeun sareng kakuatan, daya tahan, sareng kamampuan adaptasina, ngajantenkeun éta komponén penting dina rupa-rupa industri sareng aplikasi.

Bungkusan & Pangiriman

Bungkusan:

Prosés pengepakan pikeun pipa baja spiral ngalibatkeun sababaraha léngkah konci pikeun mastikeun pipa dijaga kalayan cekap salami transportasi sareng panyimpenan:

● Pangiket Pipa: Pipa baja spiral sering dihijikeun nganggo tali, pita baja, atanapi metode pangiket anu aman. Pangiket nyegah pipa individu bergerak atanapi bergeser dina kemasan.

● Panangtayungan Tungtung Pipa: Tutup plastik atanapi panutup pelindung disimpen dina dua tungtung pipa pikeun nyegah karusakan kana tungtung pipa sareng permukaan internalna.

● Tahan cai: Pipa dibungkus ku bahan tahan cai, sapertos lambaran plastik atanapi bungkusna, pikeun ngajaga tina kalembaban nalika diangkut, khususna dina pengiriman luar ruangan atanapi maritim.

● Padding: Bahan padding tambahan, sapertos sisipan busa atanapi bahan bantalan, tiasa ditambahkeun di antara pipa atanapi dina titik anu rentan pikeun nyerep guncangan sareng geteran.

● Labél: Unggal bungkus dilabélan ku inpormasi penting, kalebet spésifikasi pipa, diménsi, kuantitas, sareng tujuan. Ieu ngabantosan dina idéntifikasi sareng penanganan anu gampang.

Balanja:

● Pangiriman pipa baja spiral meryogikeun perencanaan anu ati-ati pikeun mastikeun transportasi anu aman sareng efisien:

● Moda Transportasi: Pilihan moda transportasi (jalan raya, karéta api, laut, atanapi udara) gumantung kana faktor-faktor sapertos jarak, urgensi, sareng aksésibilitas tujuan.

● Kontainerisasi: Pipa tiasa dimuat kana kontainer pengiriman standar atanapi kontainer rak datar khusus. Kontainerisasi ngajaga pipa tina unsur éksternal sareng nyayogikeun lingkungan anu dikontrol.

● Ngamankeun: Pipa-pipa diamankeun dina jero wadah nganggo metode pangiket anu pas, sapertos ngabeungkeut, ngahalangan, sareng ngait. Ieu nyegah gerakan sareng ngaminimalkeun résiko karusakan nalika transit.

● Dokuméntasi: Dokuméntasi anu akurat, kalebet faktur, daptar pengepakan, sareng manifes pengiriman, disiapkeun pikeun tujuan bea cukai sareng pelacakan.

● Asuransi: Asuransi kargo sering diala pikeun nutupan poténsi karugian atanapi karusakan salami transit.

● Pemantauan: Sapanjang prosés pengiriman, pipa tiasa dilacak nganggo GPS sareng sistem pelacak pikeun mastikeun yén pipa-pipa éta aya dina rute sareng jadwal anu leres.

● Bea Cukai: Dokuméntasi anu leres disayogikeun pikeun ngagampangkeun bea cukai anu lancar di palabuhan tujuan atanapi wates.

Kacindekan:

Bungkusan sareng pangiriman pipa baja spiral anu leres penting pisan pikeun ngajaga kualitas sareng integritas pipa salami transportasi. Nuturkeun prakték pangsaéna industri mastikeun yén pipa dugi ka tujuan dina kaayaan optimal, siap dipasang atanapi diprosés salajengna.