Panjelasan Produk

Inpormasi Standar - ASME/ANSI B16.5 & B16.47 - Flensa Pipa sareng Fitting Flensa

Standar ASME B16.5 ngawengku rupa-rupa aspék flensa pipa sareng fitting flensa, kalebet peringkat tekanan-suhu, bahan, diménsi, toleransi, panyirian, uji coba, sareng nunjuk bukaan pikeun komponén ieu. Standar ieu ngawengku flensa kalayan sebutan kelas peringkat ti mimiti 150 dugi ka 2500, ngawengku ukuran ti NPS 1/2 dugi ka NPS 24. Éta nyayogikeun sarat dina unit métrik sareng AS. Penting pikeun dicatet yén standar ieu diwatesan pikeun flensa sareng fitting flensa anu didamel tina bahan cor atanapi tempa, kalebet flensa buta sareng flensa pangurangan khusus anu didamel tina bahan cor, tempa, atanapi pelat.

Pikeun flensa pipa sareng fitting flensa anu langkung ageung tibatan 24" NPS, ASME/ANSI B16.47 kedah dirujuk.

Jenis Flange Umum

● Flensa Slip-On: Flensa ieu umumna disimpen dina ANSI Kelas 150, 300, 600, 1500 & 2500 dugi ka 24" NPS. Éta "diselipkeun kana" tungtung pipa atanapi pas sareng dilas dina posisina, ngamungkinkeun pikeun las fillet boh di jero sareng di luar flange. Vérsi réduksi dianggo pikeun ngirangan ukuran garis nalika rohangan terbatas.

● Flensa Beuheung Las: Flensa ieu gaduh hub panjang anu meruncing sareng transisi ketebalan anu lancar, mastikeun sambungan las penetrasi pinuh kana pipa atanapi pas. Éta dianggo dina kaayaan layanan anu parah.

● Flensa Sambungan Pangkuan: Dipasangkeun sareng tungtung stub, flensa sambungan pangkuan diselapkeun kana pas tungtung stub sareng disambungkeun ku cara dilas atanapi cara sanésna. Desainna anu leupas ngamungkinkeun pikeun ngagampangkeun panyelarasan nalika dirakit sareng dibongkar.

● Flensa Pangrojong: Flensa ieu teu boga beungeut anu diangkat sareng dianggo sareng cingcin pangrojong, nyayogikeun solusi anu hemat biaya pikeun sambungan flensa.

● Flensa Berulir (Disekrup): Dibor pikeun cocog sareng diaméter jero pipa anu khusus, flensa berulir dimesin nganggo ulir pipa anu meruncing di sisi sabalikna, utamina pikeun pipa bor anu langkung alit.

● Flensa Las Soket: Mirip jeung flensa slip-on, flensa las soket dimesin pikeun cocog jeung ukuran soket pipa, sahingga las fillet di sisi tukang bisa ngamankeun sambunganna. Biasana dipaké pikeun pipa bor nu leuwih leutik.

● Flensa Buta: Flensa ieu teu boga liang tengah sarta dipaké pikeun nutup atawa meungpeuk tungtung sistem pipa.

Ieu sababaraha jinis flensa pipa umum anu dianggo dina rupa-rupa aplikasi industri sareng komérsial. Pilihan jinis flensa gumantung kana faktor-faktor sapertos tekanan, suhu, sareng jinis cairan anu diangkut, ogé sarat proyék khusus. Pilihan sareng pamasangan flensa anu leres penting pisan pikeun operasi sistem perpipaan anu aman sareng efisien.

Spésifikasi

| ASME B16.5: Baja Karbon, Baja Tahan Karat, Baja Paduan |

| EN 1092-1: Baja Karbon, Baja Tahan Karat, Baja Paduan |

| DIN 2501: Baja Karbon, Baja Tahan Karat, Baja Paduan |

| GOST 33259: Baja Karbon, Baja Tahan Karat, Baja Paduan |

| SABS 1123: Baja Karbon, Baja Tahan Karat, Baja Paduan |

Bahan Flange

Flensa dilas kana pipa sareng nozzle peralatan. Ku kituna, éta didamel tina bahan-bahan ieu;

● Baja karbon

● Baja campuran rendah

● Baja tahan karat

● Kombinasi bahan Éksotik (Stub) sareng bahan pendukung anu sanésna

Daptar bahan anu dianggo dina manufaktur dibahas dina ASME B16.5 & B16.47.

● ASME B16.5 - Flensa Pipa sareng Fitting Flanged NPS ½” dugi ka 24”

● ASME B16.47 - Flensa Baja Diaméter Ageung NPS 26” nepi ka 60”

Gradasi bahan tempa anu umum dianggo nyaéta

● Baja Karbon: – ASTM A105, ASTM A350 LF1/2, ASTM A181

● Baja Paduan: – ASTM A182F1 /F2 /F5 /F7 /F9 /F11 /F12 /F22

● Baja Tahan Karat: – ASTM A182F6 /F304 /F304L /F316 /F316L/ F321/F347/F348

Diménsi Flange Slip-on Kelas 150

| Ukuran dina Inci | Ukuran dina mm | Diaméter Luar. | Flensa Kandel. | Hub OD | Panjang Flange | Diaméter RF. | Jangkungna RF | PCD | Soket Bor | Jumlah Baut | Ukuran Baut UNC | Panjang Baut Mesin | Panjang Stud RF | Ukuran Liang | Ukuran Stud ISO | Beurat dina kg |

|

|

| A | B | C | D | E | F | G | H |

|

|

|

|

|

|

|

| 1/2 | 15 | 90 | 9.6 | 30 | 14 | 34.9 | 2 | 60.3 | 22.2 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.8 |

| 3/4 | 20 | 100 | 11.2 | 38 | 14 | 42.9 | 2 | 69.9 | 27.7 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 49 | 16 | 50.8 | 2 | 79.4 | 34.5 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 19 | 63.5 | 2 | 88.9 | 43.2 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 21 | 73 | 2 | 98.4 | 49.5 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.4 |

| 2 | 50 | 150 | 17.5 | 78 | 24 | 92.1 | 2 | 120.7 | 61.9 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 27 | 104.8 | 2 | 139.7 | 74.6 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 108 | 29 | 127 | 2 | 152.4 | 90.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.7 |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 30 | 139.7 | 2 | 177.8 | 103.4 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5 |

| 4 | 100 | 230 | 22.3 | 135 | 32 | 157.2 | 2 | 190.5 | 116.1 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 5 | 125 | 255 | 22.3 | 164 | 35 | 185.7 | 2 | 215.9 | 143.8 | 8 | 3/4 | 85 | 95 | 7/8 | M20 | 6.8 |

| 6 | 150 | 280 | 23.9 | 192 | 38 | 215.9 | 2 | 241.3 | 170.7 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 8.6 |

| 8 | 200 | 345 | 27 | 246 | 43 | 269.9 | 2 | 298.5 | 221.5 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 13.7 |

| 10 | 250 | 405 | 28.6 | 305 | 48 | 323.8 | 2 | 362 | 276.2 | 12 | 7/8 | 100 | 115 | 1 | M24 | 19.5 |

| 12 | 300 | 485 | 30.2 | 365 | 54 | 381 | 2 | 431.8 | 327 | 12 | 7/8 | 100 | 120 | 1 | M24 | 29 |

| 14 | 350 | 535 | 33.4 | 400 | 56 | 412.8 | 2 | 476.3 | 359.2 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 41 |

| 16 | 400 | 595 | 35 | 457 | 62 | 469.9 | 2 | 539.8 | 410.5 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 54 |

| 18 | 450 | 635 | 38.1 | 505 | 67 | 533.4 | 2 | 577.9 | 461.8 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | M30 | 59 |

| 20 | 500 | 700 | 41.3 | 559 | 71 | 584.2 | 2 | 635 | 513.1 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | M30 | 75 |

| 24 | 600 | 815 | 46.1 | 663 | 81 | 692.2 | 2 | 749.3 | 616 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 100 |

Diménsi Flange Beuheung Las Kelas 150

| Ukuran dina Inci | Ukuran dina mm | Diaméter Luar | Kandel Flange | Hub OD | Beuheung Las OD | Panjang Beuheung Las | Bolongan | Diaméter RF | Jangkungna RF | PCD | Beungeut Las |

|

|

| A | B | C | D | E | F | G | H | I | J |

| 1/2 | 15 | 90 | 9.6 | 30 | 21.3 | 46 | Bor beuheung las dicandak tina jadwal pipa | 34.9 | 2 | 60.3 | 1.6 |

| 3/4 | 20 | 100 | 11.2 | 38 | 26.7 | 51 | 42.9 | 2 | 69.9 | 1.6 | |

| 1 | 25 | 110 | 12.7 | 49 | 33.4 | 54 | 50.8 | 2 | 79.4 | 1.6 | |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 42.2 | 56 | 63.5 | 2 | 88.9 | 1.6 | |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 48.3 | 60 | 73 | 2 | 98.4 | 1.6 | |

| 2 | 50 | 150 | 17.5 | 78 | 60.3 | 62 | 92.1 | 2 | 120.7 | 1.6 | |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 73 | 68 | 104.8 | 2 | 139.7 | 1.6 | |

| 3 | 80 | 190 | 22.3 | 108 | 88.9 | 68 | 127 | 2 | 152.4 | 1.6 | |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 101.6 | 70 | 139.7 | 2 | 177.8 | 1.6 | |

| 4 | 100 | 230 | 22.3 | 135 | 114.3 | 75 | 157.2 | 2 | 190.5 | 1.6 | |

| 5 | 125 | 255 | 22.3 | 164 | 141.3 | 87 | 185.7 | 2 | 215.9 | 1.6 | |

| 6 | 150 | 280 | 23.9 | 192 | 168.3 | 87 | 215.9 | 2 | 241.3 | 1.6 | |

| 8 | 200 | 345 | 27 | 246 | 219.1 | 100 | 269.9 | 2 | 298.5 | 1.6 | |

| 10 | 250 | 405 | 28.6 | 305 | 273 | 100 | 323.8 | 2 | 362 | 1.6 | |

| 12 | 300 | 485 | 30.2 | 365 | 323.8 | 113 | 381 | 2 | 431.8 | 1.6 | |

| 14 | 350 | 535 | 33.4 | 400 | 355.6 | 125 | 412.8 | 2 | 476.3 | 1.6 | |

| 16 | 400 | 595 | 35 | 457 | 406.4 | 125 | 469.9 | 2 | 539.8 | 1.6 | |

| 18 | 450 | 635 | 38.1 | 505 | 457.2 | 138 | 533.4 | 2 | 577.9 | 1.6 | |

| 20 | 500 | 700 | 41.3 | 559 | 508 | 143 | 584.2 | 2 | 635 | 1.6 | |

| 24 | 600 | 815 | 46.1 | 663 | 610 | 151 | 692.2 | 2 | 749.3 | 1.6 |

Diménsi Flange Buta Kelas 150

| Ukuran | Ukuran | Luar | Flens | RF | RF | PCD | Teu aya | Ukuran Baut | Baut Mesin | RF Stud | Ukuran Liang | ISO Stud | Beurat |

| A | B | C | D | E | |||||||||

| 1/2 | 15 | 90 | 9.6 | 34.9 | 2 | 60.3 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.9 |

| 3/4 | 20 | 100 | 11.2 | 42.9 | 2 | 69.9 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 50.8 | 2 | 79.4 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 63.5 | 2 | 88.9 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 73 | 2 | 98.4 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.8 |

| 2 | 50 | 150 | 17.5 | 92.1 | 2 | 120.7 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 104.8 | 2 | 139.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 127 | 2 | 152.4 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 4.1 |

| 3 1/2 | 90 | 215 | 22.3 | 139.7 | 2 | 177.8 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 4 | 100 | 230 | 22.3 | 157.2 | 2 | 190.5 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 7.7 |

| 5 | 125 | 255 | 22.3 | 185.7 | 2 | 215.9 | 8 | 3/4 | 85 | 95 | 7/8 | M20 | 9.1 |

| 6 | 150 | 280 | 23.9 | 215.9 | 2 | 241.3 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 11.8 |

| 8 | 200 | 345 | 27 | 269.9 | 2 | 298.5 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 20.5 |

| 10 | 250 | 405 | 28.6 | 323.8 | 2 | 362 | 12 | 7/8 | 100 | 115 | 1 | M24 | 32 |

| 12 | 300 | 485 | 30.2 | 381 | 2 | 431.8 | 12 | 7/8 | 100 | 120 | 1 | M24 | 50 |

| 14 | 350 | 535 | 33.4 | 412.8 | 2 | 476.3 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 64 |

| 16 | 400 | 595 | 35 | 469.9 | 2 | 539.8 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 82 |

| 18 | 450 | 635 | 38.1 | 533.4 | 2 | 577.9 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | M30 | 100 |

| 20 | 500 | 700 | 41.3 | 584.2 | 2 | 635 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | M30 | 130 |

| 24 | 600 | 815 | 46.1 | 692.2 | 2 | 749.3 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 196 |

Standar & Kelas

| ASME B16.5: Flensa Pipa sareng Fitting Flensa | Bahan: Baja Karbon, Baja Tahan Karat, Baja Paduan |

| EN 1092-1: Flensa sareng Sambunganna - Flensa Bunder pikeun Pipa, Katup, Fitting, sareng Asesoris, PN Ditunjuk - Bagian 1: Flensa Baja | Bahan: Baja Karbon, Baja Tahan Karat, Baja Paduan

|

| DIN 2501: Flensa sareng Sambungan Lapped | Bahan: Baja Karbon, Baja Tahan Karat, Baja Paduan |

| GOST 33259: Flensa pikeun Katup, Fitting, sareng Pipa pikeun Tekanan ka PN 250 | Bahan: Baja Karbon, Baja Tahan Karat, Baja Paduan |

| SABS 1123: Flensa pikeun Pipa, Katup, sareng Fitting | Bahan: Baja Karbon, Baja Tahan Karat, Baja Paduan |

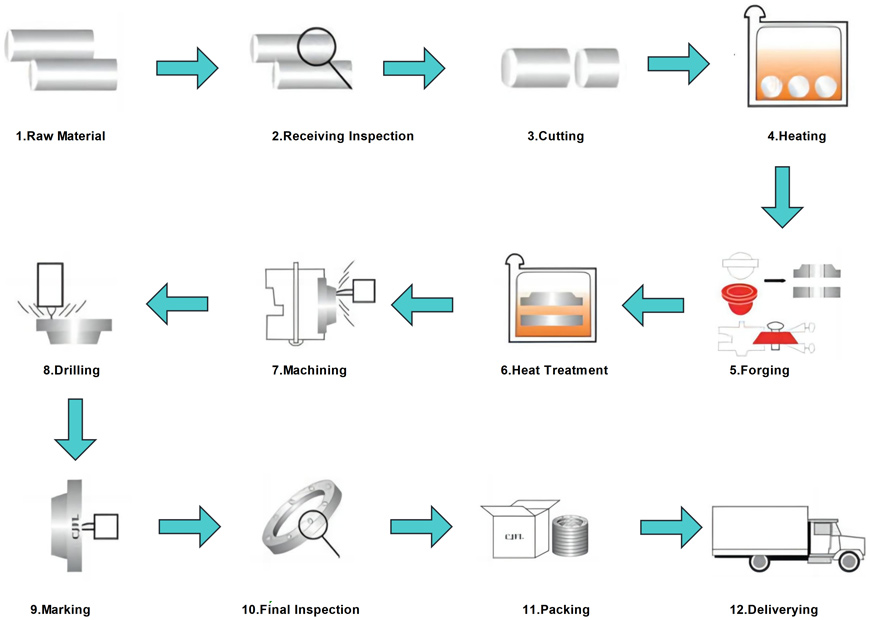

Prosés Manufaktur

Kontrol Kualitas

Pamariksaan Bahan Baku, Analisis Kimia, Uji Mékanis, Pamariksaan Visual, Pamariksaan Diménsi, Uji Lengkungan, Uji Perataan, Uji Dampak, Uji DWT, Pamariksaan Non-Destruktif(UT, MT, PT, Sinar-X,), Uji Karasa, Uji Tekanan, Uji Bocor Korsi, Uji Metalografi, Uji Korosi, Uji Tahan Seuneu, Uji Semprotan Uyah, Uji Kinerja Aliran, Uji Torsi sareng Dorongan, Pamariksaan Pengecatan sareng Pelapis, Tinjauan Dokuméntasi…..

Pamakéan & Aplikasi

Flensa mangrupikeun bagian industri penting anu dianggo pikeun nyambungkeun pipa, klep, peralatan sareng komponén pipa anu sanés. Éta maénkeun peran konci dina nyambungkeun, ngadukung sareng ngégél sistem pipa. Flensa janten komponén penting dina rupa-rupa aplikasi industri, kalebet:

● Sistem Pipa

● Katup

● Peralatan

● Sambungan

● Pangeuyelan

● Manajemén Tekanan

Bungkusan & Pangiriman

Di Womic Steel, kami ngartos pentingna kemasan anu aman sareng pengiriman anu tiasa dipercaya nalika nganteurkeun sambungan pipa kualitas luhur kami ka panto bumi anjeun. Ieu tinjauan ngeunaan prosedur kemasan sareng pengiriman kami kanggo rujukan anjeun:

Bungkusan:

Flensa pipa kami dibungkus kalayan ati-ati pikeun mastikeun yén éta sumping ka anjeun dina kaayaan anu sampurna, siap pikeun kabutuhan industri atanapi komérsial anjeun. Prosés pengemasan kami kalebet léngkah-léngkah konci ieu:

● Inspeksi Kualitas: Sateuacan dibungkus, sadaya flensa ngalaman inspeksi kualitas anu lengkep pikeun mastikeun yén éta nyumponan standar kinerja sareng integritas anu ketat.

● Lapisan Pelindung: Gumantung kana jinis bahan sareng aplikasi, flensa urang tiasa nampi lapisan pelindung pikeun nyegah korosi sareng karusakan nalika transportasi.

● Bungkusan Aman: Flensa dibundel babarengan kalayan aman, mastikeun aranjeunna tetep stabil sareng dijaga sapanjang prosés pengiriman.

● Labél sareng Dokuméntasi: Unggal bungkus dilabélan sacara jelas nganggo inpormasi penting, kalebet spésifikasi produk, kuantitas, sareng pitunjuk penanganan khusus. Dokuméntasi anu relevan, sapertos sertipikat patuh, ogé kalebet.

● Bungkusan Khusus: Kami tiasa nampung pamundut bungkusan khusus dumasar kana kabutuhan unik anjeun, mastikeun flensa anjeun disiapkeun persis sapertos anu diperyogikeun.

Balanja:

Kami damel bareng sareng mitra pengiriman anu terhormat pikeun ngajamin pangiriman anu tiasa dipercaya sareng tepat waktu ka tujuan anu anjeun tangtukeun. Tim logistik kami ngaoptimalkeun rute pengiriman pikeun ngaminimalkeun waktos transit sareng ngirangan résiko reureuh. Pikeun pengiriman internasional, kami ngurus sadaya dokuméntasi bea cukai sareng patuh kana aturan pikeun ngagampangkeun bea cukai anu lancar. Kami nawiskeun pilihan pengiriman anu fleksibel, kalebet pengiriman anu dipercepat pikeun kabutuhan anu penting.